The test was carried out with the same method illustrated several times on the site (1):

Preferment (sponge) (2): semi-wholemeal einkorn wheat flour (passing through a 600 micron sieve), sourdough in liquid form of einkorn wheat (same as the dough), brewer’s yeast in very limited quantities as a starter, water.

Final dough: preferment, einkorn wheat flour (passing through a 600 micron sieve), sourdough in liquid form of einkorn wheat (same as the dough), brewer’s yeast in very limited quantities as a starter, extra virgin olive oil, malt, salt, water.

We obtained a very fragrant bread, with an accentuated flavor of wheat, but above all with an excellent texture and very digestible.

The long maturation with the sourdough (always made with the some einkorn wheat) has allowed us to achieve these results.

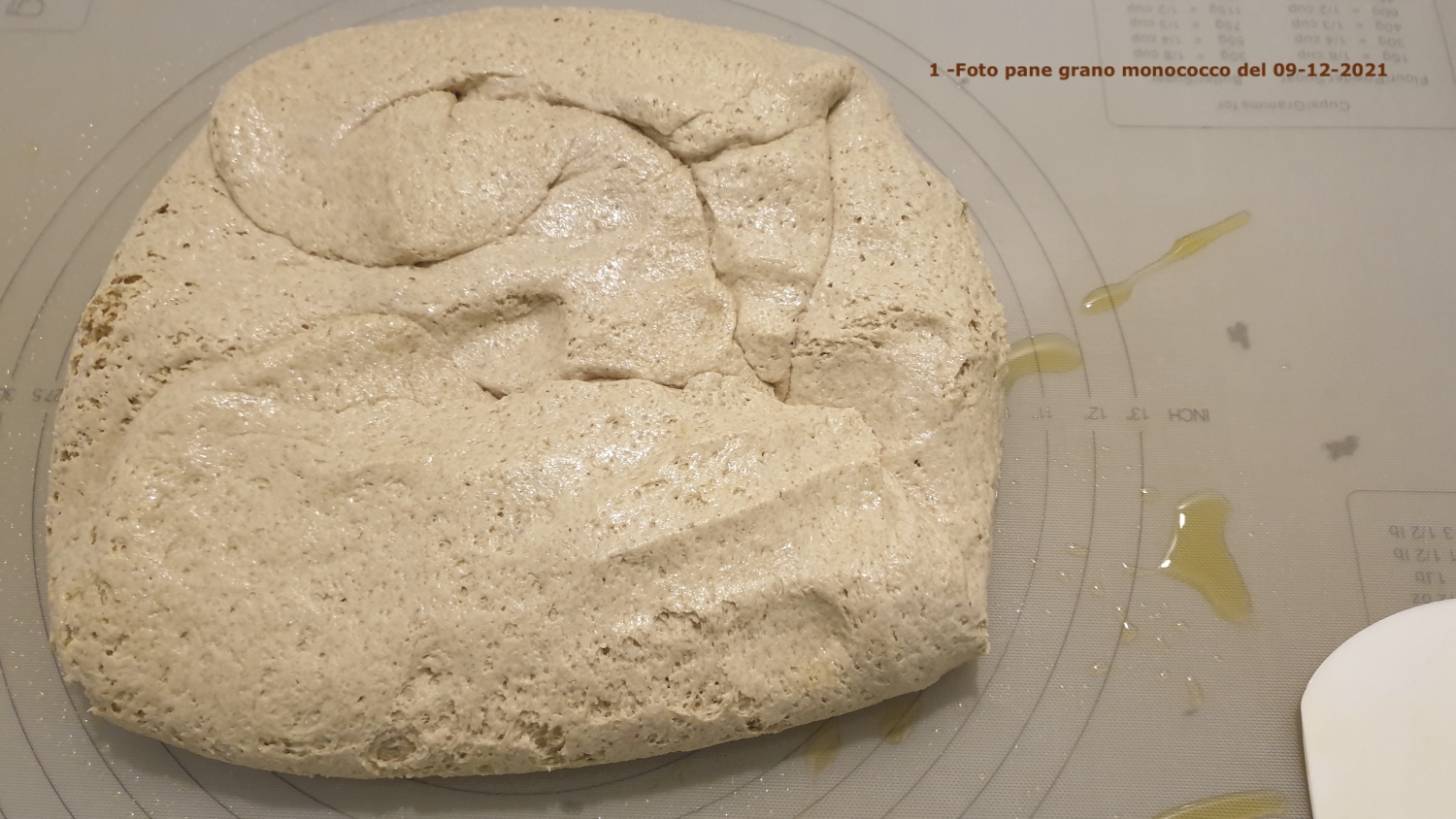

The hydrolysis of gluten by the sourdough is clearly visible in Photo n. 1: after the very long cold maturation (5 degrees) and the subsequent heating up to 19-20 degrees, the dough has an underdeveloped, indeed “deteriorated” gluten network. The formation of the “loaf” or “roll” with the usual technique is not possible, the dough does not lend itself to “modeling”. A ball or roll is therefore made for final proof in a basket (Photo N. 2). Photo No. 3 shows the dough at the end of leavening ready for the oven; the surface does not appear homogeneous or elastic. The result Photo NN. 4 and 5 show the success of the test and above all the photos NN. 6, 7, 8, 9 are tangible proof of the excellent result of the texture which presents a disordered crumb in the distribution of the holes but definitely present: the bread is not compact at all. Looking at the state of the dough (Photo N.1) it would not seem possible to obtain the result shown in photo n9!.

Photo n. 1