Einkorn bread100% (suitable for people sensitive to gluten / wheat not celiac)

Scientific research has long highlighted, in addition to the great digestibility and richness of mineral contents, also the high tolerability of some varieties of enkir wheat (https://glutenlight.eu/en/2019/03/11/tolerability-of-the-monococcum-wheat/) For this reason we dedicate particular attention to this grain.

In summary some of the possible difficulties are:

1. The least amount of gluten

2. The lower strength of gluten

3. Damaged starch (1)

4. Amylase too weak (falling number greater than 350). (2)

Furthermore, the creation of products for people who are sensitive to gluten / wheat but not celiac requires long maturation times for the dough so that the enzymatic processes also operate the transformations (hydrolysis) of starches and gluten (https://glutenlight.eu/en/2019/03/12/maturation-and-fermentation-of-a-mixture-of-water-flour-and-yeasts-and-or-lactic-bacteria/).

Long maturation times (over 24 hours) are not compatible with the stability of this type of dough at room temperature or above. Low temperature (4-6 degrees) a retarder prover (cold rooms for leavening control) must be used to slow the leavening and to help the maturation of the dough (or, for home preparations, the refrigerator). Once the maturation is over, it will then proceed rapidly to leavening/proofing. It must be used, because the product is designed for people sensitive to gluten / wheat but not celiac, the sourdough of the same grain we use or the most digestible and tolerable einkorn wheat. This sourdough will not give great contribution to leavening. Furthermore, the lack of gluten does not generate an abundant nor strong gluten network: we risk having a low and compact bread. You will have to introduce air into the dough during preparation.

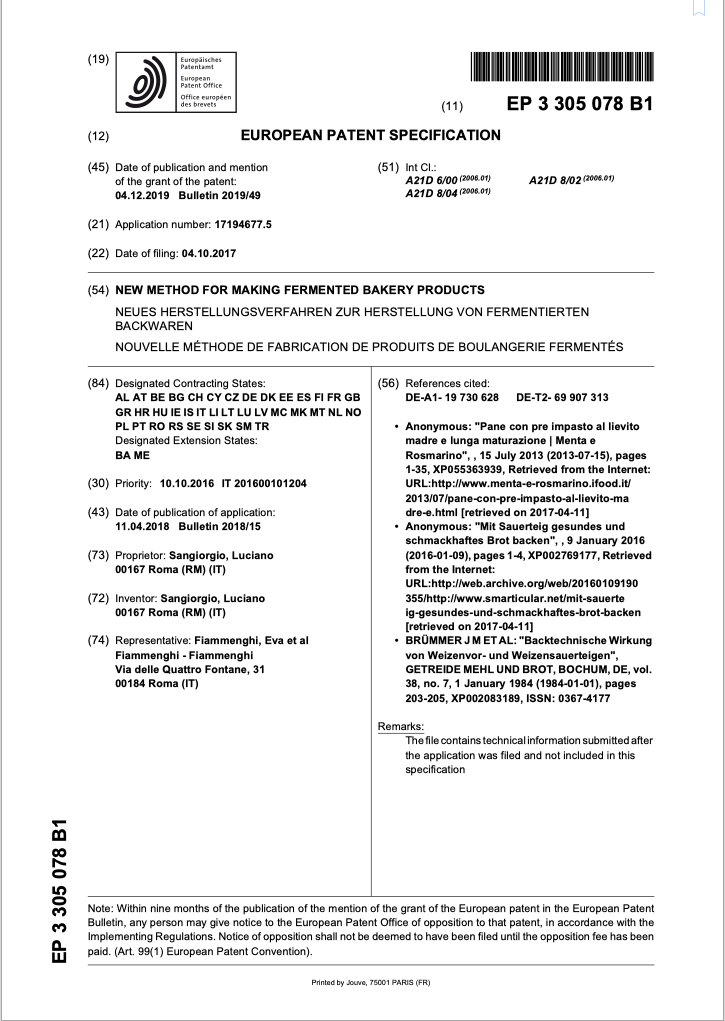

You will have to use a very limited percentage of fresh compressed Brewer’s yeast that has the function of starter and collaboration with the lactobacilli. The flour to be used should always be from organic cultivation: the use of nitrogen compounds increases both the percentage of gluten and strength and alters the glutenin gliadin ratio. (https://glutenlight.eu/en/2019/03/14/fertilizers-and-wheat/). These notes are part of a new industrial method for making dough for bread and dry products suitable with gluten-poor flours (limited percentage of gluten and limited “gluten strength”). They are the flours that, in current practice, are not used for the production of bread. A first step we do using a simplified version (direct method) of the a new industrial method (1) that involves the construction of the pre-ferment followed by the final dough. Furthermore the method was adapted for a home preparation, so without the use – for example – a retarder prover with controlled temperature and humidity.

Times and temperatures have been defined for a semi-wholemeal einkorn flour, stone-ground. This clarification is necessary, because especially times and temperatures vary according to the flour (type and harvest) and its degree of refining (quantity of bran present). Further clarification: the method is for expert people.

Method – recipe

Ingrendients

65% hydration (800gr. X65% flour = 520gr. Water)

| autolisi | dough | ||||

| 1 | flour | 400gr. | 400gr. | ||

| 2 | Water | 400gr. | 120gr | ||

| 3 | LiCoLi | 80gr. | |||

| 4 | Brewer’s yeast | Compressed fresh | 0,5gr. | dissolved in very little water

|

|

| 5 | Malt | 0 | 9,6gr. | 1,2% of total flour | |

| 6 | Salt | 0 | 14,4gr. | 1,8% of total flour | |

1 step: refresh the sourdough as liquid batter not as stiff dough twice made with the same einkor wheat flour in a row and use it well mature (preparation times vary depending on the room temperature, on average 4 hours + 4 hours).

2 step: prepare autolysis (3) with 400gr. of flour and 400gr. of water, both cold (from refrigerator).

3 step: mix autolysis with 90gr. of water using a blade blender (used to incorporate air inside). The water temperature must be cold (from refrigerator).

4 step: add brewer’s yeast, LiCoLi and malt and blend again for 1 minute.

5 step: using the planetary mixer with the hook, prepare the final dough by adding all the flour still available and the remaining water (more or less to have a homogeneous dough) to the mixture described in the previous step and make it homogeneus ( it is not necessary to “string”).

6 steps: if there is any flour left on the bottom of the planetary mixer, complete by hand.

7 step: put the dough in a plastic bowl, greased with seed oil, with lid in a room at about 18 degrees for 8 hours (you can use a plastic box with lid and ice inside).

8 step: then put the bowl with the dough in the fridge for 13 hours checking that the temperature is not higher than about 18 degrees so that in the cold the dough matures but little leavens, very little; the leavening will take place later.

9 step: take the bowl from the fridge, cover it only with a cloth and place it on a hot plan for food (the one used in the rotisseries) heated to 30 degrees for 2 hours.

10 steps: pour the dough on a pastry board lightly greased with seed oil (resting on the warm surface), manipulate (make folds) the dough for about 2-3 minutes, give it the shape of a roll, cover the dough with cloth place it on a hot plan for food to 26-28 degrees for about 1 hour (less if it tends to break).

11 steps: give the desidered shape to loaf and place it in a leavening basket type banneton (coated with greaseproof paper). Place the basket, covered with a cloth, on a hot plan for food at 30 degrees for about 1 hour or as needed for proofing.

12 step: turn the dough on a baking sheet and bake.

13 steps: average cooking time 1 hour (depending on the type of oven). Static cooking, possibly with a water pot inside.

Note:

1 – step n. 3, 4, 5, and 6: total time approximately 30 minutes

2 – the flour and water must have a temperature so that the dough has a temperature of about 18 degrees at the end of the 6th step.

3 – NEVER use dusting flour.

4 – Doughs with flours with weak and low gluten have a gluten network with limited stability and strength. By heating the dough from below we preserve the surface a little from the early breakages.

5 – If the dough after refrigerator time has a broken surface, reduce the time of step n. 7 increasing by the same measure that of step n. 8.

6 – The dough witheinkorn flour in long maturations tends to release part of the water absorbed making the dough sticky: if excessive decrease the hydration (less water in step n. 5).

7 – These doughs are very hydrated and when they are put in the baking sheet they will tend to give a low bread. To obtain a bread, as in the photo, a plumcake type container should be used, handmade with the bottom of the oven aluminum containers; the soft walls of the container will allow the dough to “take” its own shape.

IMPORTANT: Buy Einkorn 100% semi-wholemeal wheat flour avoiding Monlis (because it has a very indigestible fraction –type 33mer). Hammurabi wheat is very difficult to use.

(1) – The conditions of grinding a grain determine the degree of damage starch, influencing the characteristics of the flour; a modest damage can be beneficial, an excessive degree is undesirable. The undamaged starch granules swell and gelatinize only weakly at the temperature good to kned dough and leavening, while for the damaged ones the process takes place almost totally. The starch granules, not damaged by grinding, during the dough fermentation process are not attacked by beta-amylase and only slowly by alpha-amylase which transforms them into maltose. In contrast, the crushed granules are hydrolyzed by amylases. The use of too finely ground flour, with a high percentage of damaged granules, leads to the formation of bread with a lower volume than normal, with moist and badly cooked crumb, characterized by an excessively dark color of the crust.

(2) – If the amylases are too active (Falling Number values lower than 220 seconds) the final products will have a flat shape, moist and sticky crumb and dark crust. If, on the other hand, it is greater than 350, this flour will have a weak amylase activity and the final product will be little developed and with compact and dry crumb.

(3) – The autolysis technique allows to reduce the mixing time, to obtain a dough whose consistency becomes particularly smooth and malleable; is also more easy shaping the loaf and the finished product has a higher volume, a better bubbles and a greater softness of the crumb.

Deepening

THE IMPORTANCE OF DAMAGED STARCH. It increases water absorption and provides extra nutrition for the yeast. A high level of damaged starch would result in sticky dough that produces a weak side wall and a sticky crumb (if enough amylolytic enzymes are available). The level of starch damage directly affects the water absorption and the dough mixing properties of the flour and is of technological significance. Damaged starch absorbs 2 to 4 times more water than regular starch granules. Sticky doughs, high water absorption, longer proofing times, and red bread crust color are just some of the effects of damaged starch. Damaged starch granules are susceptible to enzymatic degradation in comparison to native starches. Better knowledge of levels of damaged starch in flours is essential for better screening of flour. The optimum DS value varies with the use of the flour and is greatly dependent upon the flour protein content, the alpha amylase activity, and the type of bread to be made from the flour.

Pane farina grano monococco Podere Pereto

Note:

(1) New Method For Making Fermented Bakery Products (Ing. Sangiorgio Luciano – Rome)

Back